Iron removal by aeration system

Published on by Tirellil Wissem, Project manager in Case Studies

dear all,

I need a system to remove iron from a well water, using aeration system.

the flow rate of 720 m3/h with an iron content of 1 mg/liter in the raw water and a PH value of 7.9.

Can you explain how to :

choosing the required volume of the iron removal tank and the design

The air (oxygen)flow to be injected to oxidize the iron and how to choose the blower

After oxidize system we will use a sand filter

Thanks

Taxonomy

- Aeration

- Water Wells

- Well Drilling

- Water Well Casing

- Biological Oxygen Demand (BOD)

- Membrane Aerated Biofilm Reactor (MABR)

- Standard Oxygen Transfer Rate (SOTR)

- Air Blowers

3 Answers

-

Answer from You.com

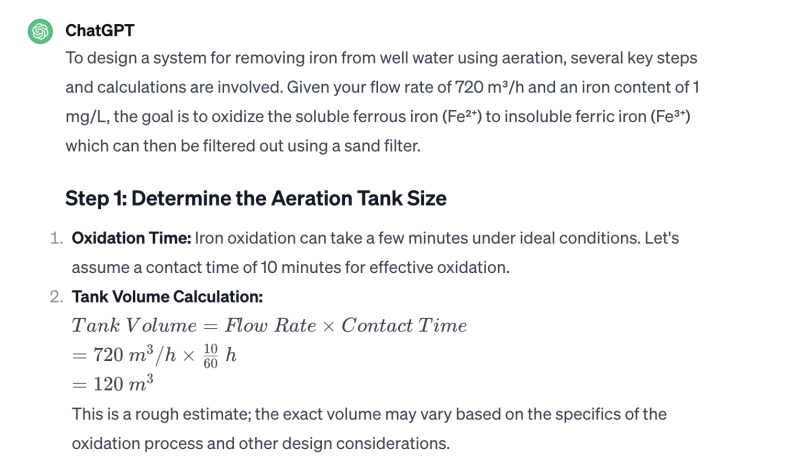

To design an iron removal system using an aeration system, you will need to consider the required volume of the iron removal tank, the air flow needed for oxidation, and the choice of a blower. Here's a step-by-step guide:

1. Determine the Required Volume of the Iron Removal Tank:

The volume of the iron removal tank will depend on the flow rate of the water and the desired contact time for effective iron removal. In this case, the flow rate is 720 m3/h. To calculate the required volume, you need to determine the contact time required for effective iron oxidation and removal. The contact time can vary depending on the specific system and water quality, but a common range is 5-15 minutes.

Let's assume a contact time of 10 minutes. To calculate the required volume of the iron removal tank, use the following formula:

Volume of Tank (m3) = Flow Rate (m3/h) x Contact Time (h)

Volume of Tank = 720 m3/h x (10/60) h = 120 m3

Therefore, you would need an iron removal tank with a volume of 120 m3.

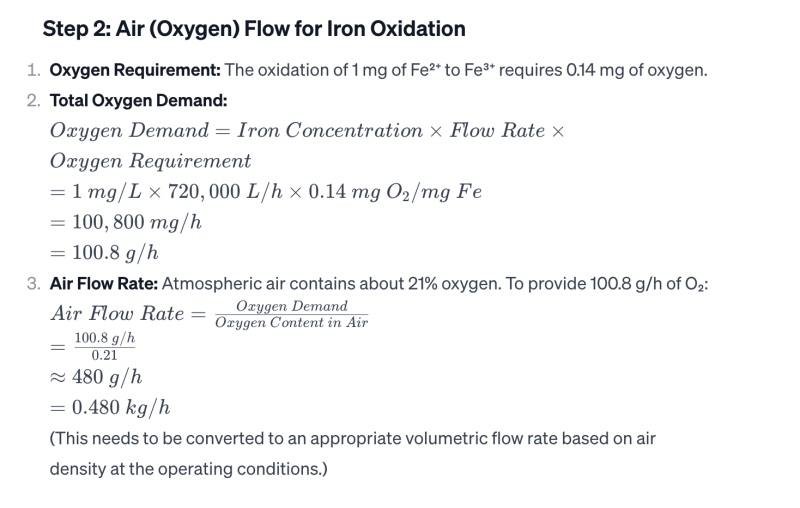

2. Determine the Air Flow for Oxidation:

Aeration is used to oxidize the ferrous iron (Fe+2) to ferric iron (Fe+3), which can then be filtered out. The amount of air flow required depends on the iron content in the water and the desired level of oxidation. In this case, the iron content is 1 mg/liter.

To determine the air flow, you can refer to the water treatment guidelines or consult with a water treatment specialist. They can provide specific recommendations based on the iron concentration and water quality. It's important to ensure that sufficient air is injected to achieve complete oxidation of the iron.

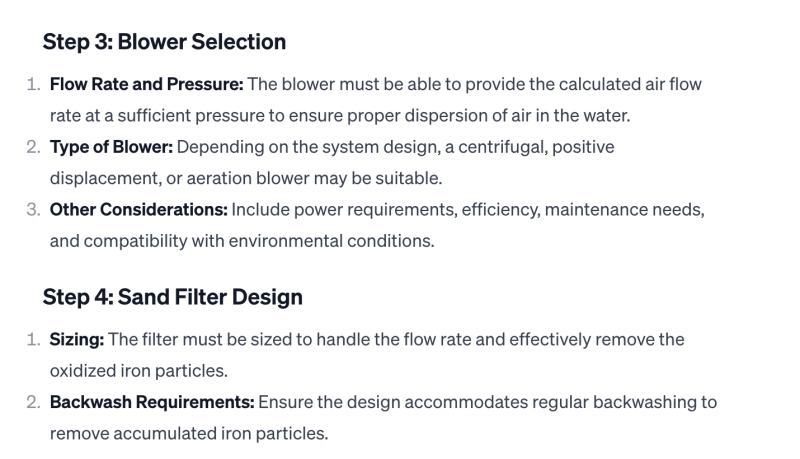

3. Choose the Blower:

To inject air into the water for oxidation, you will need a blower. The blower should be capable of providing the required air flow determined in the previous step. The specific blower selection will depend on factors such as the system design, pressure requirements, and available power supply.

When choosing a blower, consider its capacity, efficiency, and reliability. It's recommended to consult with a water treatment specialist or supplier who can help you select the appropriate blower for your specific needs.

4. Sand Filter:

After the iron is oxidized, it can be removed using a sand filter. The sand filter will trap the oxidized iron particles and provide clean water. The design and size of the sand filter will depend on the flow rate and the level of iron removal required. It's important to properly size the sand filter to ensure efficient filtration and prevent clogging.

Consider factors such as the filter media, backwashing requirements, and maintenance when selecting a sand filter for iron removal.

Remember to consult with a water treatment specialist or supplier for detailed design recommendations and to ensure compliance with local regulations.

I hope this helps you understand the process of designing an iron removal system using an aeration system. Let me know if you have any further questions!

-

Here is how CHAT GPT answered this question:

-

his could be of your use https://ultraaqua.com/product/ultratron-advanced-oxidation-process-uv-systems/