How to Use a Color Reducer for a Waste Water Plant?

Published on by Rayan Ahmed in Academic

Hi there all,

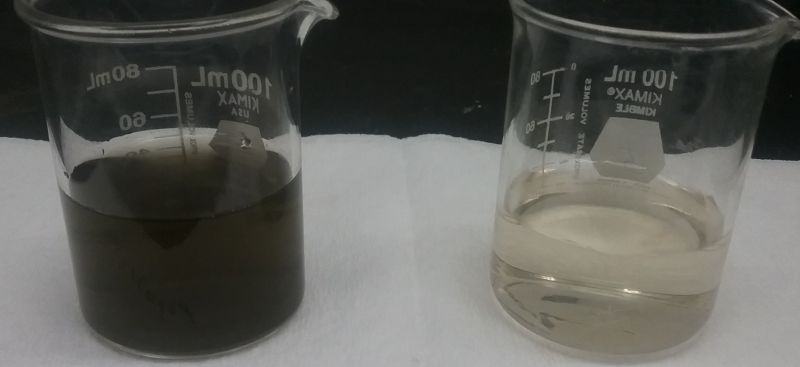

I have a problem in my WWTP plant. The color is very high, as well as COD.

I heard that color reducer agent can remove color from water and I would like to know in which stage do I have to use the color reducer - in primary treatment or in tertiary treatment? In which ppm do I have to use it?

Currently, the chemical dosage is:

- Lime 1000 ppm

- Alum 1200 ppm and poly 1 ppm

- Color reducer ??? ppm

Kindly share you experience guys.

Thanks/Regrads,

Abdul Gaffar - Senior Chemist.

Taxonomy

- COD Removal

- Industrial Wastewater Treatment

- Waste Water Treatments

- Wastewater Treatment

- Utility Chemicals

- Treatment Chemicals

16 Answers

-

Hi Gaffar,

There are many ways to reduce color and COD in any wastewater system as biological treatment (effective ins most of the cases to reduce COD and color), use of some oxidants (I think ozone is the best for the color removal) and other technoologies. Even you can use the biological treatment and after a clarification and filtration the ozone dosing, it will be really effective if after the biological you could continue hanving any residual COD or color.

If the COD is recalcitrat, it is not recommended the use of biological treatment, but you could continue considering on long run the ozone use due to its high effectiveness.

If we we want have a good and confidence system to remove the COD and color, we need know more information about this wastewater (industry, lab analysis, WWTP, flow, size of the plant and units, some operation description and other important data) that can drive to a good suggestions for your case.

Regards,

Orlando D. Gutiérrez Coronado -

CRC can be added before primary clarifier as well as before secondary/lamella clarifier. The dosage would be up to 1000 ppm. CRC addition in tertiary treatment not required because it won't work without special provision.

Treatment scheme can also show some scope of improvement for better results.

-

Dear gaffar,

Can you share with us your influent and effluent characteristics (pH, BOD, COD, TSS, Turbidity, Color, Starch, flow, DO), along with treatment scheme. Your COD and TSS both would be high. There is no rule of thumb for dosage optimization of lime, alum, poly and colour removal chemicals. It should be jar tested at lab for optimum permutation and combination for getting the desired result. The ideal dosage for Color removal chemical can go up to 1000 ppm depends upon the quality of waste water and treatment scheme. Please note CRC is not cheap. It will add high treatment cost per annum.

We have seen several factors contributing to high COD and most of the technology failed in meeting the discharge norms. I can solve your issue please share the details with me. You can reach me at sushantkuma@gmail.com.

-

There are various ways to reduce color. There is none as best method. The best method is one which suites your effluent. You have to try these out yourself at your specific site.

Firstly you may just add Ferric Alum. This reduces color due some color dyes used in textiles

You may use Color removal resins. You may use color removal resin from Thermax or from Purolite or Ion Exchange. The color removal resins are to be used in a column like regular ion exchange unit. However, you should have preceeding unit using Polyelectrolyte Lime alum also.

-

I have had great success with color removal using our Aquapure process. You can contact me at rdeal@hubbardhall.com if you want more information.

-

In your case, I advise you after primary treatment to apply biological treatment with active silt or other (secondary treatment). After that, solve the problem of the most simple and effective color removal using a color reducer or other (tertiary treatment).

1 Comment

-

I'm with Mr.Gediminas. In our textile ETPs when no pre-anaerobic stages are, conventional CMAS could easily provide a yellow pale effluent. Downstream we dose decolouring agent (often quaternary cationic polymer) to comply with quality at discharge. That's.

We had excellent results on sulphur black with coupled anaerobic-aerobic bio processes, where low ORP and reductive environment (ANA) strongly promoted/helped a fully-biological decolouring.

HTH

-

-

It depends of your effluent but our company has experience using some specific polymers in textile industry and in tertiary treatment and alum, lime and polymer in effluents from pulp and paper industry also in tertiary treatment. ood luck for you.

-

Is Saferex available in USA? I have some color that we have tried everything on. Very little change.

50,000 gpd is flow

1 Comment

-

Hi Gerald, please email me at shawn@o3water.co.za

We can discuss getting you some SaferEx to evaluate on your water condition.

-

-

the answer to your present question of color reducers could be 50 to 100ppm

-

color can be biodegraded if there is a proper biotreatment facility. u can conduct lab trials with anaerobic and aerobic methods. after biological treatment u can remove biological color if present in tertiary treatment with minimum doses of color reducers and hence minimum sludge.

-

Hiii... can you say in my opinion you can change the lime quantity & may be easily remove the color & second thing feric coagulant is costly so you can use lime.

-

Do not dose lime in colored water ,Feric coagulant ( FeCl3) is best for colored contain water , another way , You can dose Hypo chlorite (12%) in water,give retension time min 4 hr for it ,continue it 5 days ,ur water color will disappear .

For COD removal , pass it through Primary clarifier with proper chemical dosing , COD will be minimized .

-

Hi Abdul. Have your considered SaferEx product? It is a lower cost product created & patented in Africa which we recently tested in South Africa with great results. The additive is Eco safe and performs well to bind to all suspended sediment and other factors causing discoloration.

-

Dear Gaffar,

The COD and color removal is one of the most important problems that can be solved if you have a good designed and operated biologic plant.

In most of the cases using just our biological treatment you can remove both till a good level to safety dispose the treated wastewater. We can supply a very good biocleaner system that can remove both. Our system can release good microorganisms to treat the wastewater, and they are produced in a bioreactor submerged in the treatment tanks. Using it you must not need dose microorganisms or chemicals to treat the water.

Even if after the removal you can not reach the disposal level, you could use any chemical oxidant. I suggest you evaluate the ozone as the most powerful oxidant you can find.

We can help you with the entire project if you send us the lab data, removal requirement and other data.

Regards,

Orlando D. Gutiérrez Coroinado -

Dear Mr. Gaffar

Please email your requirement to lalit@aboutfilter.com

Also send your phne number so we can offer a suitable solution.

We use combination of precipitation, advanced oxidation to reduce dye colours from streams

-

Some of my clients use decolorizer to remove color .And the outlet water is pretty good .