pH correction methods

Published on by Demang Mahmud in Technology

Dear members, we are getting drinking water from a private well since 2006. Since 3 months the water started appearing little rusty. We did the analysis and found out that there is corrosion in pipeline as the Ph level of water is 5 which is low. We can not change the piping since its not very old and its expensive to replace the whole pipe line. Please tell us how to increase the ph level of water before it enters to the pipe line?

Taxonomy

- Water

- Alkaline

- Water Utility

- Corrosion Prevention

- Pipes and Pipelines

24 Answers

-

http://www.gaiam.com/discover/185/article/increase-alkalinity-water/

-

Your question is three years old, was it answered?

http://www.gaiam.com/discover/185/article/increase-alkalinity-water/

-

The Water Network research team has consolidated an answer to the above question.

Further input from members is welcome and appreciated.

Lets understand what is pH?

pH is a numeric scale that indicates the acidity of an aqueous solution.

It is the negative logarithm to base 10 of the molar concentration of hydrogen ions, measured in units of mol/l.

The pH scale has a range from 0 to 14, with the 7 indicating a neutral point.

- Solutions with a pH below 7 are acids.

- Solutions with a pH above 7 are bases.

- Distilled, pure water is neutral, neither acid nor a base, and has a pH of 7.

Pure water is neutral, but when it is mixed with chemicals it can change its acidity. Additionally, mixing acids and bases can neutralize their effects.

Causes of pH variations in water:

- Soil composition through which the water moves, in its bed and as groundwater. Certain rocks can neutralize the acid while others have no effect.

Limestone can buffer – neutralize the acidification of freshwater. - Number of plants and organic matter in the water. Carbon dioxide is released when they decompose, and if forms the carbonic acid as it combines with water. It is a weak acid but in greater amounts in will lower the water pH.

- Chemicals in the water released by industries or individuals. Industrial effluents that are released in the environment, therefore, are required to have a certain pH value.

- Acid precipitation. Acid rain occurs when nitrogen oxides (NOx) and sulfur dioxide (SO2) in the air are combined with water vapor. They are products of car fumes and emissions from coal-fired power plants.

- Coal mine drainage. Sulfuric acid is formed when iron sulfide, which is found around coal mines, is combined with water.

pH standards for drinking water:

Environmental Protection Agency (EPA) maintains strict standards for appropriate pH levels in drinking water. Consuming excessively acidic or alkaline water is harmful, warns the EPA. Drinking water must have a pH value of 6.5-8.5 to fall within the EPA standards , and they further note that even within the acceptable pH range, slightly high- or low-pH water can be unappealing for several reasons. High-pH water has a slippery feel, tastes a bit like baking soda, and may leave deposits on fixtures, according to the EPA website. Low-pH water, on the other hand, may have a bitter or metallic taste, and may contribute to fixture corrosion.

pH adjustment systems:

There are two primary types of system design for pH adjustments – continuous and batch.

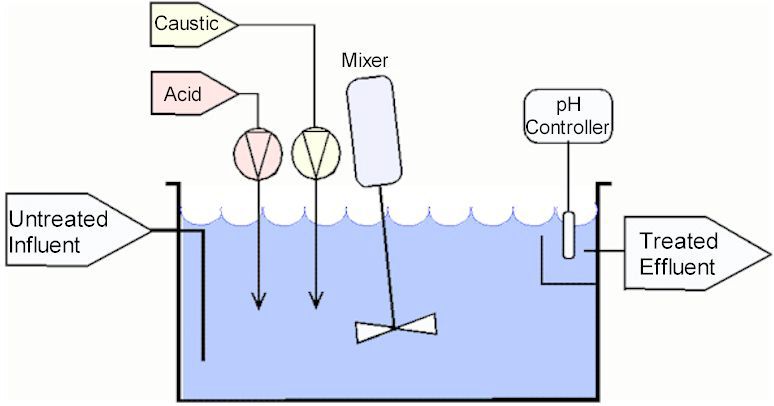

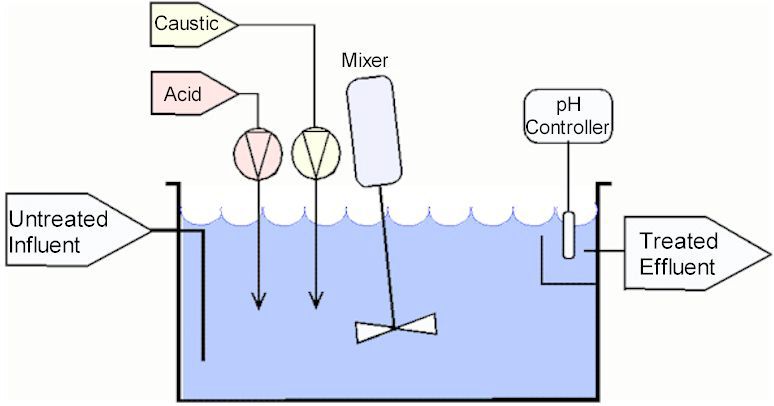

Continuous flow

Diagram 1: Continuous flow system.

Diagram 1: Continuous flow system.

Source: phadjustment.comThe tank is constantly full – the amount of influent entering it equal to the treated effluent exiting the tank.

The advantage of this system is that can handle relatively high flows. However, it is not certain that the effluent will always be in range.

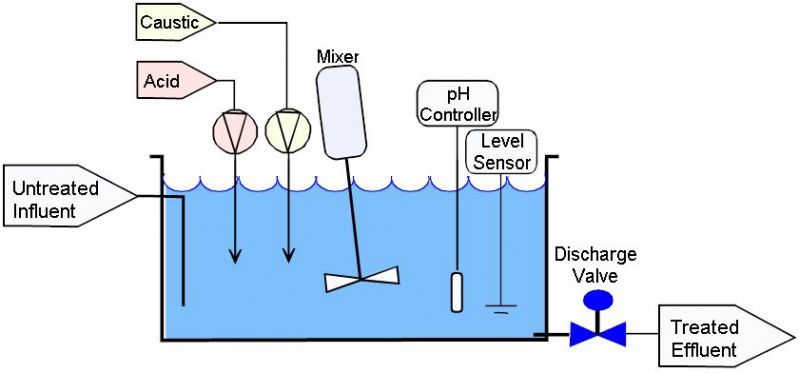

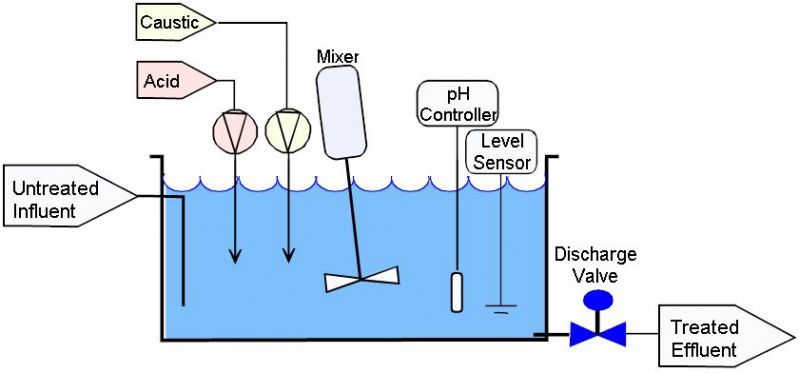

Batch

Diagram 2: Batch adjustment system

Diagram 2: Batch adjustment system

Source: phadjustment.comThe batch has a fixed water volume, which is discharged only after fulfilling the criteria.

The influent enters the tank anywhere convenient and exits due to gravity near the bottom, where the port is located.

The batch volume is treated in one cycle.

** The systems shown here are simplified.

pH adjusting methods:

Raising the pH

Lowering the pH

Neutralizing filters

Acid injections

MgO beads

CO2

Soda ash/sodium hydroxide injections

Neutralizing filters

Neutralizing filters are used if drinking water is acidic.

The pH is increased by the addition of the neutralizing material.

It is important to highlight that the water hardness may increase.

(Water hardness is the amount of dissolved calcium and magnesium in the water - dissolved bicarbonate minerals - calcium bicarbonate and magnesium bicarbonate.) Neutralizing filters are point-of-entry devices.

Water with pH greater than 6 is treated with calcium carbonate (limestone) and water with the pH below 6 is treated with the synthetic magnesium oxide.

Untreated water passes through a filter filled with either calcium carbonate or a synthetic magnesium oxide medium and the material dissolves in the water therefore raising the pH level.

The flow rate should not the greater than 2 l/s·m2. The bed should be deep enough to provide sufficient contact time.

The material in the neutralizing filter need refilling and regular backwaching.

If cartridge filters, that retain solids from passing through, are installed before the neutralizing filters, the neutralizing filters will last longer.

After the neutralizing filter a water softener can be added to regulate the water hardness.

The neutralizing filter may result in pressure loss, since the water passes through the finely ground neutralizing material.

The corrosion of the pressure tank and the well pump may occur since the neutralizing filters are installed after the pressure tank.

In case of a high flow rate, liquid injection systems are a better solution.

Magnesium oxide beads in combination

Prill MgO beads are used when the water pH needs to be rasied.

They should be used after reverse osmosis.

Osmosis is a spontaneous movement of the molecules in the solvent through a semi-permeable membrane. The molecules tend to “go” to the in that direction that will equalize the concentrations of the two sides. Reverse osmosis is a process in which the particles move in the opposite direction than in natural osmosis. The contaminated fluid passes through the membrane and the suspended particles are separated from the liquid. For this process, pressure is needed – the hydrostatic pressure needs to be greater than the osmotic pressure.

Prilly Pure Water Beads raise and balance pH levels of the water to 8,7 without any chemicals.

The beads are made from magnesium oxide which is produced from naturally occurring salts of magnesium found in rich brine deposits located approximately 2,500 feet below ground. The resulting magnesium oxide is ‘prilled’ into small, hard pellets by a high temperature firing process which turns them into small ceramic-like pellets.

In addition to adjusting the pH, the beads lower the surface tension of water, remove toxins and pull out heavy metals from water.

Prilly Pure Water Beads last forever and never need to be replaced.

Injection systems:

I Soda ash/sodium hydroxide injection

Soda ash/sodium hydroxide injections are used if the water is acidic.

When injected into a water system, soda ash (sodium carbonate) and sodium hydroxide raise the pH of water.

Injection systems are a point-of-entry system.

Soda ash or sodium hydroxide solution are injected in the water by a corrosion-resistant chemical feed pump.

The injections are installed before the pressure tank so that the tank ant plumbing systems are protected from corrosion.

Dual treatment is used if the water needs to be disinfected, in addition to being neutralized. A chlorine solution is added with the neutralizing chemical.

With the injection systems water with low pH can be effectively treated – as low as 4.

The chemical storage tanks need to be refilled occasionally.

II Acid injection

Acid injection is used for water with a high pH.

Water with a higher pH can have a soda-like taste that is eliminated with this treatment and the chlorination is improved.

Acid injection is a point-of-entry system.

Acid injection reduces pipe corrosion, since water with the pH above 9 corrodes brass, copper, zinc, aluminum and iron.

A solution of acetic acid is injected into water. Usually white vinegar is used, as it is the cheapest, but citric acid and alum are also an option, as well as more hazardous weak solutions of hydrochloric acid or sulfuric acid if the pH is above 11.

The chemicals need to be refilled occasionally, while wearing the protective goggles, gloves and clothing.

Carbon dioxide

Carbon dioxide is used to reduce pH in alkaline water.

Carbon dioxide, CO2, is a colorless and odorless gas. It is a chemical compound composed of a carbon atom covalently double bonded to two oxygen atoms.

It is used as a pretreatment and sulfuric acid is added in the second step. The main purpose of this secondary acidification is to reduce the bicarbonate content and avoid calcium carbonate precipitation.

Carbon dioxide does not corrode the pipes and the equipment.

It was gives better control of pH than sulfuric acid. It shows self-buffering when reaching neutral pH levels. The self-buffering enables precise end-point control eliminating the danger of lowering the pH too much.

It can be utilized via a completely automated system.

Documents on TWN about pH and drinking water standards:

- WHO guidelines for drinking-water quality

- WHO pH in drinking-water

- EPA drinking water standards and health advisories table

- pH Control in WTP by the Addition of CO2

- Drinking Water Treatment - pH Adjustment

- pH Requirements of Freshwater Aquatic Life

- What is pH and How is it Measured?

- pH Theory and Practice

- The Theory of pH Measurement

-

The Water Network research team has consolidated an answer to the above question.

Further input from members is welcome and appreciated.

Lets understand what is pH?

pH is a numeric scale that indicates the acidity of an aqueous solution.

It is the negative logarithm to base 10 of the molar concentration of hydrogen ions, measured in units of mol/l.

The pH scale has a range from 0 to 14, with the 7 indicating a neutral point.

- Solutions with a pH below 7 are acids.

- Solutions with a pH above 7 are bases.

- Distilled, pure water is neutral, neither acid nor a base, and has a pH of 7.

Pure water is neutral, but when it is mixed with chemicals it can change its acidity. Additionally, mixing acids and bases can neutralize their effects.

Causes of pH variations in water:

- Soil composition through which the water moves, in its bed and as groundwater. Certain rocks can neutralize the acid while others have no effect.

Limestone can buffer – neutralize the acidification of freshwater. - Number of plants and organic matter in the water. Carbon dioxide is released when they decompose, and if forms the carbonic acid as it combines with water. It is a weak acid but in greater amounts in will lower the water pH.

- Chemicals in the water released by industries or individuals. Industrial effluents that are released in the environment, therefore, are required to have a certain pH value.

- Acid precipitation. Acid rain occurs when nitrogen oxides (NOx) and sulfur dioxide (SO2) in the air are combined with water vapor. They are products of car fumes and emissions from coal-fired power plants.

- Coal mine drainage. Sulfuric acid is formed when iron sulfide, which is found around coal mines, is combined with water.

pH standards for drinking water:

Environmental Protection Agency (EPA) maintains strict standards for appropriate pH levels in drinking water. Consuming excessively acidic or alkaline water is harmful, warns the EPA. Drinking water must have a pH value of 6.5-8.5 to fall within the EPA standards , and they further note that even within the acceptable pH range, slightly high- or low-pH water can be unappealing for several reasons. High-pH water has a slippery feel, tastes a bit like baking soda, and may leave deposits on fixtures, according to the EPA website. Low-pH water, on the other hand, may have a bitter or metallic taste, and may contribute to fixture corrosion.

pH adjustment systems:

There are two primary types of system design for pH adjustments – continuous and batch.

Continuous flow

Diagram 1: Continuous flow system.

Diagram 1: Continuous flow system.

Source: phadjustment.comThe tank is constantly full – the amount of influent entering it equal to the treated effluent exiting the tank.

The advantage of this system is that can handle relatively high flows. However, it is not certain that the effluent will always be in range.

Batch

Diagram 2: Batch adjustment system

Diagram 2: Batch adjustment system

Source: phadjustment.comThe batch has a fixed water volume, which is discharged only after fulfilling the criteria.

The influent enters the tank anywhere convenient and exits due to gravity near the bottom, where the port is located.

The batch volume is treated in one cycle.

** The systems shown here are simplified.

pH adjusting methods:

Raising the pH

Lowering the pH

Neutralizing filters

Acid injections

MgO beads

CO2

Soda ash/sodium hydroxide injections

Neutralizing filters

Neutralizing filters are used if drinking water is acidic.

The pH is increased by the addition of the neutralizing material.

It is important to highlight that the water hardness may increase.

(Water hardness is the amount of dissolved calcium and magnesium in the water - dissolved bicarbonate minerals - calcium bicarbonate and magnesium bicarbonate.) Neutralizing filters are point-of-entry devices.

Water with pH greater than 6 is treated with calcium carbonate (limestone) and water with the pH below 6 is treated with the synthetic magnesium oxide.

Untreated water passes through a filter filled with either calcium carbonate or a synthetic magnesium oxide medium and the material dissolves in the water therefore raising the pH level.

The flow rate should not the greater than 2 l/s·m2. The bed should be deep enough to provide sufficient contact time.

The material in the neutralizing filter need refilling and regular backwaching.

If cartridge filters, that retain solids from passing through, are installed before the neutralizing filters, the neutralizing filters will last longer.

After the neutralizing filter a water softener can be added to regulate the water hardness.

The neutralizing filter may result in pressure loss, since the water passes through the finely ground neutralizing material.

The corrosion of the pressure tank and the well pump may occur since the neutralizing filters are installed after the pressure tank.

In case of a high flow rate, liquid injection systems are a better solution.

Magnesium oxide beads in combination

Prill MgO beads are used when the water pH needs to be rasied.

They should be used after reverse osmosis.

Osmosis is a spontaneous movement of the molecules in the solvent through a semi-permeable membrane. The molecules tend to “go” to the in that direction that will equalize the concentrations of the two sides. Reverse osmosis is a process in which the particles move in the opposite direction than in natural osmosis. The contaminated fluid passes through the membrane and the suspended particles are separated from the liquid. For this process, pressure is needed – the hydrostatic pressure needs to be greater than the osmotic pressure.

Prilly Pure Water Beads raise and balance pH levels of the water to 8,7 without any chemicals.

The beads are made from magnesium oxide which is produced from naturally occurring salts of magnesium found in rich brine deposits located approximately 2,500 feet below ground. The resulting magnesium oxide is ‘prilled’ into small, hard pellets by a high temperature firing process which turns them into small ceramic-like pellets.

In addition to adjusting the pH, the beads lower the surface tension of water, remove toxins and pull out heavy metals from water.

Prilly Pure Water Beads last forever and never need to be replaced.

Injection systems:

I Soda ash/sodium hydroxide injection

Soda ash/sodium hydroxide injections are used if the water is acidic.

When injected into a water system, soda ash (sodium carbonate) and sodium hydroxide raise the pH of water.

Injection systems are a point-of-entry system.

Soda ash or sodium hydroxide solution are injected in the water by a corrosion-resistant chemical feed pump.

The injections are installed before the pressure tank so that the tank ant plumbing systems are protected from corrosion.

Dual treatment is used if the water needs to be disinfected, in addition to being neutralized. A chlorine solution is added with the neutralizing chemical.

With the injection systems water with low pH can be effectively treated – as low as 4.

The chemical storage tanks need to be refilled occasionally.

II Acid injection

Acid injection is used for water with a high pH.

Water with a higher pH can have a soda-like taste that is eliminated with this treatment and the chlorination is improved.

Acid injection is a point-of-entry system.

Acid injection reduces pipe corrosion, since water with the pH above 9 corrodes brass, copper, zinc, aluminum and iron.

A solution of acetic acid is injected into water. Usually white vinegar is used, as it is the cheapest, but citric acid and alum are also an option, as well as more hazardous weak solutions of hydrochloric acid or sulfuric acid if the pH is above 11.

The chemicals need to be refilled occasionally, while wearing the protective goggles, gloves and clothing.

Carbon dioxide

Carbon dioxide is used to reduce pH in alkaline water.

Carbon dioxide, CO2, is a colorless and odorless gas. It is a chemical compound composed of a carbon atom covalently double bonded to two oxygen atoms.

It is used as a pretreatment and sulfuric acid is added in the second step. The main purpose of this secondary acidification is to reduce the bicarbonate content and avoid calcium carbonate precipitation.

Carbon dioxide does not corrode the pipes and the equipment.

It was gives better control of pH than sulfuric acid. It shows self-buffering when reaching neutral pH levels. The self-buffering enables precise end-point control eliminating the danger of lowering the pH too much.

It can be utilized via a completely automated system.

Documents on TWN about pH and drinking water standards:

- WHO guidelines for drinking-water quality

- WHO pH in drinking-water

- EPA drinking water standards and health advisories table

- pH Control in WTP by the Addition of CO2

- Drinking Water Treatment - pH Adjustment

- pH Requirements of Freshwater Aquatic Life

- What is pH and How is it Measured?

- pH Theory and Practice

- The Theory of pH Measurement

-

Low pH drinking water

As per Mr. Maqbool Hussain comment, more important than the technical problem (Pipe corrosion) is the health problem. That water is producing indesirable effects on the health of the consumers.

People involved in water supply have a moral responsability with consumers, and thus, water must be delivered in a healthy way.

It's clear that the water must be conditioned, and apart of raising the pH, Langelier Index, alkalinity and hardness must be taken to acceptable levels.

Lime or calcite must be added in order to achieve the above goals.

Depending of the amount of CO2 in the water, CO2 addition could be needed as well.

Lime has a lower capex but higher opex than calcite. (Lime needs double amount of CO2 than Calcite).

Water must be conditioned until reaching the equilibrium state (No changes with time), this means that the final state will have the same amount of CO2 than the atmosphere.

-

The pH has changed or not. Maybe pH has been 5 during a lot of time and you haven't noticed. Have you noticed the problems at the same time you change the pipes? You must investigate what is happening. To adjust the pH I prefer sodium bicarbonate food grade. Strong alkalis have chemical dangers and are more dificult to manege and achieve a fine adjust. The pH curve change very quick with these products.

-

Water reacted with rusted pipeline during transportation, hence water is contaminated with iron, for which water became acidic and pH is reduced to 5. There is a simple & low cost solution. Please filter your water through TERAFIL red clay candle (an invention of the undersigned) before use. It will increase pH to more than 6, and simultaneously remove all iron, suspended & turbid particles, bacteria, colour etc and also improve taste of the water. S.Khuntia, Inventor of TERAFIL water purification tech, Ex-Chief Scientist of CSIR, Govt of India, Freelance Consultant.

-

induce lime

-

Immediate solution is to dose soda ash (sodium bi carbonate). check for reasons for low pH.

-

Water Solution

Look at using our technology to create your own water from the air: www.ecoloblue.com we can increase the ph level 7 to 10.

-

you should check for metals in water

If your water is coming out of the ground with a pH of 5 you may have other issues you should be worried about. A pH like that could indicate reducing conditions and there are certain harmful metals that are more likely to be in solution in such water (i.e. arsenic). Raising the pH might mitigate these concerns but you should know what is there first. If you haven't already you should collect a sample for typical metals found in groundwater.

-

Lime can be added to water to increase its pH level. It is safe.

-

In my view, the most urgent issue that need to be addressed is the pH (5) of the water if it is being drunk as it is. The drinking water with this pH level can be extremely harmful for the health. It can eat away human body in the similar way it is damaging the pipes. Therefore, pH needs to be raised immediately. A combination of lime, soda or soda ash should work well. Secondly, the well water should be analyzed to see if it falls within the WHO guidelines at least. If not, it should be treated to remove the undesired constituents. Thirdly, I assume the iron pipeline should have been internally lined or coated and raising pH should stop further damage. Anyways, damaged portions will have to be replaced. In case, most of the pipeline is rusted and leaking, it would be wise to replace the it with corrosion resistant material such as PVC or HDPE. However, make sure the material can sustain the network pressure.

-

IS this RO water? If so reminerialization is what is needed. Regardless, there are many ways to raise the ph, lime, soda, calcium carbonate etc all work well when done properly. Which one you choose may depend on the local availability. Dosing/injection or side stream will most likely have the lowest capex.

-

Check your ways and means of disinfecting your drinking water.. I suggest that you use NaOCl, it is effective as bleaching agent and disinfectant,..and its pH at 40% purity is between 13 to 14. See if this can help. For now I really do not understand fully what is your problem.. is it the corrosion and rusting of pipelines? or the low pH of drinking water? Corrosion and rusting develops through time when your material is not appropriate, High pH or low pH. Its a matter of time .

-

Desalination Consultant

Just add lime. By doing so you will raise the Langelier saturation index level in the water thus self-coating of the pipe will take please and isolate steel from water and prevent rust..

-

Dear Member It appears the well water is being used as drinking water and supplied thru' iron pipes. Is the water treated before distribution ? If so, add a Calcium Carbonate ( Marble chips ) filter after final treatment. This will increase the pH as well give life to water. Using iron pipes on the distribution line is not advisable. Stainless Steel is preferable but costlier. Use food grade plastic pipes.

-

pH control

Dear member. You can use sodium hydroxide, but I need to know what is your process of treatment because I think you have not only problem with pH, I think you have another problem.

-

Muhammad suleman Chandio

Since, it has been decided that replacement of pipeline is not sustainable. Hence only following solutions are recomended:

1- The rust removal from pipelines should be arranged by available equipments.

2- What ever pipes which are most deterioted and holes are seen, those pipes be replaced.

3- The catholatic protection should be ensured to avoid corrosion.

4- The domestic treatment tablets etc can raise pH but further consequances may also be explored/ investigated by research councils/ institutes to save human health by any such additives if any.

-

A method commonly used is filtration through a calcium carbonate bed (marble, sea shells etc). Pre-mixed filter media for this are available. Best is a sidestream filtration, allowing for precise target pH adjustment.

-

PH Correction

Hello,

You can ad soda ash to the final water to increase the PH.

You can also use ozone to raise the ph 3 points.

Rick Wadley

-

BY adding backing soda

-

Use PVC or HDPE pipeline

Try to replace the pipeline with PVC or HDPE pipeline which are cheaper than iron pipes and they are corrosion resistant. For adjusting pH, you can use food grade Baking soda.

-

You have to change the pipeline,which makes the water unfit for drinking. if you want to increase the Ph of water you can use baking soda or alkaline or ph drops from health food stores. But best way is to replace the pipeline as it may contaminate the water more in future. Purify the water before consumption.