Preventive solution for odor pollution from WWP trickling plant

Published on by Carlos Dela Cruz

Dear All,

We are constructing wastewater treatment plant very close to the city centre.

Right now we are using wet scrubbers as they can handle higher flow rates and pollutant concentrations.

The site is about 150-200 meters away from the existing local residents.

Can someone suggest better technology and options for odour pollution control?

We want to avoid the complaint from the residents.

Your opinion and recommendation are highly appreciated.

Taxonomy

- Water

- Treatment

- Sewage Treatment

- Water Treatment & Control

- Waste Water Treatments

- Pollution

- Sewage

- Wastewater Treatment Plant Design

- Urban Water Infrastructure

- Sewer Networks

- Plant Engineering

23 Answers

-

We have the same problem here for so many years...things a improving slowly but very expensive...I would recommend to look at the latest technology,affordable and do away with holding ponds or oxidising..This is a real time treatment system to do away with odour ...should you need more information I will be happy to help....danny@viroment.com

-

Don't build it there.

-

Dear All,

Thanks for all your contribution in solving the future problem. We would convince the client and designer for these options. The expected completion date still end of next year 2017.

We will inform you on any update soon.

Best Regards,

Carlos

-

We have very successfully totally abated malodour at several municipal waste water plants in several countries. Our product is 100% organic and extremely easy to use. Please take a look at our website and then contact us for technical help. www.soleco-technology.com

-

solve the problem at source, the below answers pertain to older technologies and are right in their own way. But the best way to eliminate odour is to have High DO in the WWTP. We use a pre-programed liquid to generate dissolved/molecular oxygen in water which solves a number of problems and reduces electricity, sludge outputs and Eliminates odour. ( suspended molecular oxygen is created)

The industry is saturated with bacteria and enzyme based products which are pretty much the same and require specific conditions temperatures etc. the other option is acids and well we all know how bad they are.

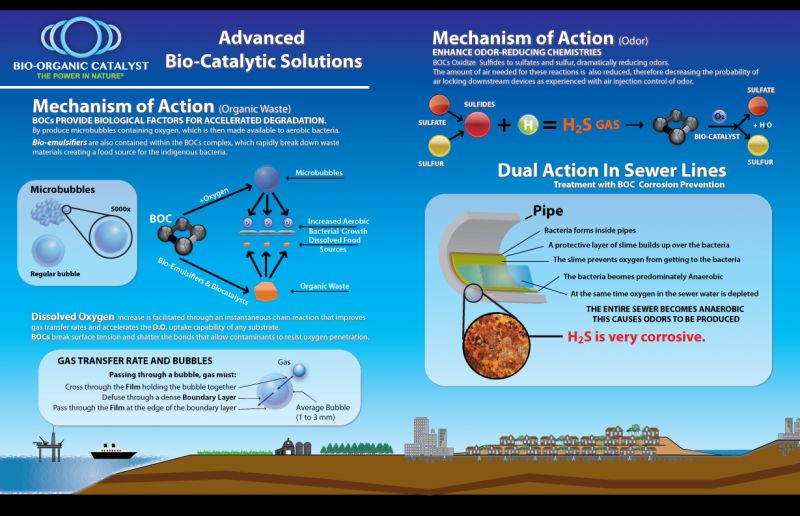

Technologies like Bio-Organic Catalyst is new and Protein based ( all enzymes are proteins BUT NOT ALL proteins are enzymes) and breaks down compounds into elements in a nutshell.

another simpler explanation : it increases the gas transfer rates

Made from proteins and minerals it is has the ability to seed oxygen in water, soil and air. Before anyone says its expensive,

no its not the dilutions/application is 1ppm (one) for every 100 BOD. So the actual product is very inexpensive and very effective.

Below is a chart as to how the technology works. Fell free to ask any questions

-

need to install odour removal scrubbers with scientifically covered hoods and ducts

-

Our Solutek product removes malodor generally within 3 to 7 days. Our product is 100% organic.

-

Check out h2o2.com we use hydrogen peroxide to prevent odor. Feel free to email me at kathleen.l.swanson@gmail.com with any questions

-

Our company has a 100% organic solution that has been taking care of odor control in major cities for over 25 years. www.soleco-technology.com

After 3 to 5 days there is no odor whatsoever.

Email us for references or contact me directly on - pettman@soleco-technology.com

Thanks.

-

Our company has a 100% organic solution that has been taking care of odor control in major cities for over 25 years. www.soleco-technology.com

After 3 to 5 days there is no odor whatsoever.

Email us for references or contact me directly on - pettman@soleco-technology.com

Thanks.

-

Hi Carlos,

The best way to manage odor pollution control is to use breakthrough filter change indicators on your scrubbers. Please see below the link to some of the Chemteq indicators that would work great with your scrubbers. The indicators are real-time indicators so there is no need to guess when you need to change your filters. Thus preventing odor polution. My e-mail is jessica@chemteq.net if you have any questions. Thanks

http://chemteq.net/products/filterchangeindicators.html

-

Yes, check out www.bio-organic.com

-

We can provide additional information for odour control and would be happy to speak with you. In the meantime, you can find quite a lot of pertinent information on our website: GA-GreenChem.com We look forward to hearing from you!

-

The best odour control is Ozone. check websites for companies who are leaders in the field like Ozonia and Xylem.

Dr.

-

We would recommend a biofilter loaded with pumice odour control media. We have supplied this media throughtout Europe and get removal rates for H2S of 98%+.

Please see our website for further information: http://www.lava-rock.com/lava-rock-odour-control/

Eddie

-

You need to say what process you are using for the biological stage and what is happening to the sludge. An indication of location (ambient temperature) and throughflow would also be useful. Otherwise - why on earth did you decide to build it there???

-

Dear Carios dela,

Odour pollution is a threat not just too human health and welfare, but also to air quality, as it contributes to photochemical smog formation and particulate secondary contaminant emissions. Odour from wastewater treatment plants is caused by emissions, such as volatile organic compounds and sulphur compounds like H2S, Mercaptants.

SO4 2- + 2C + 2 H2O →2HCO3- + H2S

It has traditionally been a low priority, but its importance has been increasing with more stringent environmental legislation.

There are two main types of technologies to treat odour

1. Physical/chemical

2. Biological

Physical/chemical technologies remove bad-smelling emissions by changing them with chemicals (chemical scrubbers), burning (incinerators) and by adsorbing the emissions with carbon

Biological technologies remove emissions using filter systems, made partially or completely from organic materials (Biofilters), that pass the emissions upwards whilst simultaneously trickling a cleansing solution downwards (bio trickling filters). Other biological technologies aerate the sludge or sewage with fine bubbles (activated sludge diffusion).

Biofiltration and active carbon filtration require the most materials

Incineration requires the most energy.

“On the basis of their high efficiency at reducing odour and low environmental impact, activated sludge diffusion and bio trickling filtration appear to be the most promising technologies. The high water consumption of bio trickling filters could be reduced by using effluent or recycled water.”

Biological aeration tanks and secondary settling tanks must be aerobic to function efficiently. Keeping these units aerobic is the most important odour control consideration. The two major sources of objectionable odours in activated sludge tanks are development of anoxic or anaerobic conditions in the aeration tank and entry of dissolved odorous compounds into the aeration tank. As the first odour source, poor mixing or inadequate dissolved oxygen in the mixed liquor impairs the aerobic environment, causing settled deposits with resultant anaerobic conditions at the bottom of the tank. Because most diffusers can become clogged, routine cleaning is necessary. If the plant is equipped with swing-type, air-diffusion piping, operators can change clogged diffusers and flush air headers without emptying the aeration tanks. Mechanical aerators with the highest turbulence levels typically produce the highest odour and VOC emission rate, followed by coarse-bubble diffusers. Because of the low level of turbulence, fine-bubble diffusers typically have the lowest emission rate assuming all other factors.

As the second odour source, even with aerobic conditions, dissolved oxygen compounds may enter the tank with the primary clarifier effluent or with anaerobic return sludge flows; aeration then releases the compounds to the atmosphere. Aerosols formed during the aeration process can be carried by air currents far beyond the local tank environment. Both of these problems require control at the source.

Regards,

Prem Baboo

-

Dear Carlos,

I guess that this is an activated sludge process with primary works and sludge treatment too, all being sources of odors mainly due to H2S, mercaptants, VFAs for the nastiests and detergents too. Wet scrubbers with chemicals are fine, fouled air recycling through the activated sludge tank(s) is an option, ferric chloride or equivalent added at the inlet works will stop H2S.

Air flows are probably high so efficiency/yield in terms of contact time (ie size of equipment) is a key driver added to operating costs (energy for air fans + chemicals + maintenance + byproducts if any).

Do not hesitate to get back in touch, in particular because more info about the context of this plant woule be needed.

Best regards,

V. Urbain

-

Dear Carlos,

I guess that this is an activated sludge process with primary works and sludge treatment too, all being sources of odors mainly due to H2S, mercaptants, VFAs for the nastiests and detergents too. Wet scrubbers with chemicals are fine, fouled air recycling through the activated sludge providing you've got enough contact time is an option, biofiltration another one but it needs space. More expensive but compact you may find

-

Hi Carlos, have you considered the addition of iron chlorides for sulfides precipitation?

-

the easiest and most convenient way is to use a biocleaner unit for odor control.

very easy to use. installs in minutes and will be effective in less than 2 days.

very cheap, very easy to try. risk free.

you will not smell a thing inches away from the treatment ponds.

-

Hi There,

We have both wet chemical scrubbers, and bio-bark bed odor scrubbers in our contract.Both of which work well most of the time, but have draw backs. The bark bed does not cope well with hogh flows or really pungent odors, and the chemical scrubber I operate uses a lot of chemiclas, pH maintenance is tricky and we have added chlorine on top of the caustic soda to add efficiency.

The best scrubber my company operates is a duel chemical wet scrubber, with two media towers in series, one dosing caustic soda liquid to pH 10, then either peroxide or chlorine.

This two step attack seems to do a great job removing odor, and the large facility using this, negates all odors to the boundary.

Hope that helps.

-

you have to change technical of waste water treatment , it is seems working by physical treatment ,so it emission odor pollution

change it to chemical treatment (active bacteria)