Measuring the True Performance Of VFDs

Published on by Eliseo Jose Jr Mocas, Proprietor at ESM Motion Control & Automation System in Technology

Specific energy consumption is the secret to the success of your variable-frequency drive (VFD) driven pumps!

Imagine the following scenario:

You have just completed the installation of variable frequency drive on your deepwell pump. For the past four (4) years you have been trying to convince management that changing the conventional auto-transformer submersible motor control will solve the following problems:

- Throttling the discharge output because your pump was over-designed, discharging more than the needed output to satisfy system demand.

- High power consumption due to the same reason above.

With the new VFD, you are very satisfied with the performance. You are now producing the right capacity at the required head and as expected power consumption was reduced.

You succeed at last.

Before you congratulate yourself, think again.

Have you really found the right solution to the problem?

Most water service providers resort to the use of variable frequency drives, expecting that reduced power consumption is the ultimate solution to the problem of over-sized pump installation. Sadly, for some, reducing the output is a retrogressive solution to the shortage in available water supply. They reduced deepwell output, but they still fell short of providing 100% supply to the concession area.

In some cases, the use of VFD even contributed to increased cost of production which adversely affected

their tariff rate.

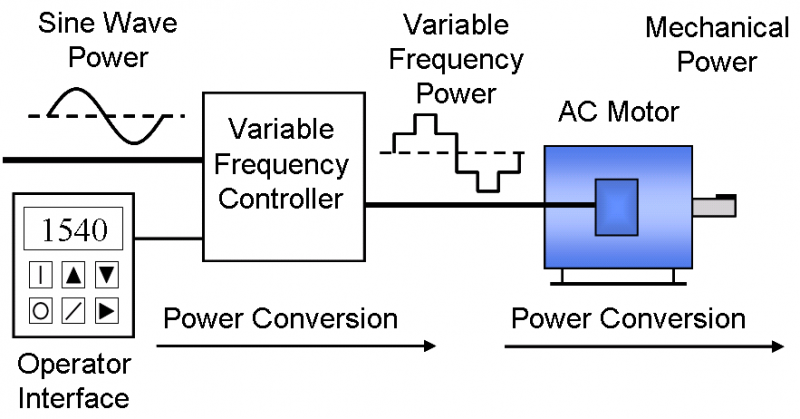

How do you measure the effectiveness of VFD solution intended for energy efficiency optimization ?

The key performance indicator (KPI) of effectiveness in the use of variable frequency drive is the specific energy consumption, expressed as kw/hr per volume of water pumped. It is the amount of energy expended per unit volume of water pumped.

Before deciding on changing your motor control to VFD, analyze the impact on hydraulic performance of your system. The adverse impact is more pronounced in deepwell pumps with deep settings (very low pumping level), where the ratio of surface discharge pressure to the total dynamic head is very small.

More often than not, the shift in the operating point from fixed speed to variable speed for pump system with high static head will result to increased specific energy consumption. The speed change can result in an operating point with lower pump efficiency, motor efficiency and power factor. The decrease in flow and total dynamic head may not be enough to produce proportional reduction in power consumption.

Higher specific power consumption will result to increased production cost and affect the profitability of water distribution operation.

An unbiased and reliable audit performed by a competent professional is in order prior to implementation to insure optimum pump system performance.

Media

Taxonomy

- Water

- Pumping System Design

- Energy

- Water Supply

- Development & Management

- Pumps

- Energy

- Energy Consumption

- Pumps

1 Comment

-

FABTASTIC , FANTASTIC energy consumption