What would be the best way of reducing COD levels prior to a Bioreactor?

Published on by Gary O. Shaw MIET MCIM, Simpsons Malt Limited - Water Treatment Specialist in Technology

Hi,

We run an AMBR system at our site. The COD levels have risen substantially lately and the blowers are struggling to reach D.O.(Dissolved Oxygen) set points. All process water is collected in a sump, transferred to a balance tank which undergoes DAF before going into the Aerobic - bio tank.

Please suggest some methods for reducing COD levels prior to a Bioreactor.

Thanks.

Taxonomy

- Anaerobic Digestion

- Bioreactor

- COD Removal

- Biological & Chemical Quality

- Wastewater Treatment

14 Answers

-

The use of an AOP (Advanced Oxidation Process) can sometimes be more economical than hauling off waste that is too high in COD. You can reduce the COD substantially and increase your BOD:COD ratio for the recalcitrant compounds in the stream that may not be able to be consumed by the facultative bacteria. We are experts in AOP, especially Fenton's Reagent. Please give me a call if you have any questions or concerns. I am happy to help you. I may be reached on my mobile phone at (239) 989-3581. In the interim, please take a look at our website for more information about our company, offerings and AOP in general. It is chalked full of great information, even if you use it just for a resource. www.usptechnologies.com

Thanks,

Sean L. Roop

-

The Water Network research team has consolidated an answer to the above question.

Further input from members is welcome and appreciated.Chemical Oxygen Demand (COD) is a measurement of all organic and inorganic compounds in water.

It is related to Biological Oxygen Demand (BOD), which is the amount of oxygen required for the bacteria to degrade the organic compounds in water.

COD is practical for testing water quality in surface waters and wastewater since it determines organic pollutants.

COD is the mass of oxygen consumed per solution [mg/l] and almost all organic compounds can be oxidized to carbon dioxide (CO2) in acidic conditions with a strong oxidizing agent.

Potassium permanganate, ceric sulphate, potassium iodate, and potassium dichromate are the oxidizing agents used to determine COD.

Potassium dichromate (K2Cr2O7) is the most effective and it is not too expensive, is easy to purify and can completely oxidize most of organic compounds.

If the BOD/COD ratio of untreated wastewater is 0.5 or greater, the waste is easily treatable by biological methods. If the ratio is below about 0.3, either the waste may contain toxic components or acclimated microoorganisms may be required in its stabilization.

To reduce COD and BOD there are a couple of methods to be used:

- Chemical methods

- Physical methods

- Physico-chemical methods

Secondary treatment of the industrial wastewater treatment plant i.e. biological treatment such as activated sludge process, sequential batch reactor, upflow anaerobic sludge blanket reactor, etc. is used to remove BOD .

For, COD removal, primary treatment of the industrial wastewater treatment plant i.e. settling, advanced oxidation, physio-chemical, etc. are used.

- Physical methods:

Screening is the primary treatment in a wastewater treatment plant. It is used to remove garbage which would pose problems downstream causing clogging and damage. It separates and gets rid of rags, paper, plastic and metals.

The space between the screening bars differs and determines the efficiency of screening:

- Fine screening - under 10 mm

- Medium screening - 10 to 40 mm

- Coarse screening - over 40 mm

The screening bar needs to be cleaned manually or automatically and this reduces the frequency of screenings.

Diagram 1: Screening

Source: wateronline.com/doc/wwema-window-slots-vs-holes-in-preliminary-treatment-screening-0001Sand and/or Multi Media Filtration filters the suspended and dissolved solids. Secondary filtration is often needed. though, as smaller solids may pass through.

Membrane Filtration removes suspended and dissolved solids solids thanks to barrier membranes (microfiltration and ultrafiltration) or semipermeable membranes (nano and reverse osmosis)

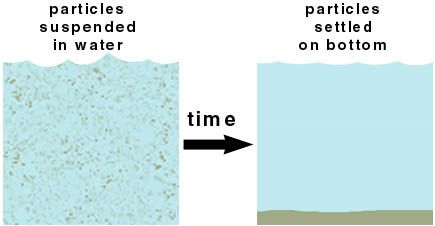

Sedimentation relies on gravity to naturally remove suspended solids in still water.

If the water is undisturbed, solid particles will settle at the bottom of the sedimentation tank, depending on the size of the particles. They will further be mechanically removed by clarifiers.

The particles will settle if:

- the ascending water velocity is lower than the limit sedimentation velocity, in a vertical ascending flow

- ratio length/height of the tank is greater than water velocity/limit sedimentation velocity, in a longitudinal flow.

Settleable solids are the visible volume accumulated at the bottom of an Imhoff cone after water has settled for an hour.

Diagram 2: Sedimentation

Source: sswm.info/content/sedimentation- Physico-chemical methods:

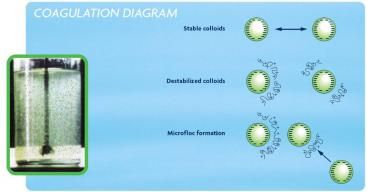

Coagulation is a water treatment process in which chemicals (coagulants) are added to the water.

It neutralises charges and forms a gelatinous mass to trap particles, forming a large mass that settles or is trapped in the filter.

Coagulation and flocculation are relatively simple and cost-effective, provided that chemicals are available and dosage is adapted to the water composition.

In colloidal suspensions the particles would settle very slowly or not at all, since they carry surface charge. Same charges repel each other. Coagulants are added in order to agglomerate the particles.

Coagulants can be classified into:

· inorganic coagulants (e.g., aluminum and ferric salts)

· synthetic organic polymers (e.g., polyacryl amide derivatives and polyethylene imine)

· natural coagulants .

All of them are very efficient at turbidity removal from water.

Coagulation with Aluminium- and Ferric-based coagulants, followed by disinfection by chlorinating is one of the most used methods of water treatment.

Water pretreatment by oxidation might be necessary when using them.

When the coagulants are added to water and stirred for a few minutes they dissolve.

Coagulation destabilises the charge of the particles.

Coagulants with charges opposite to those of the suspended solids are added to the water to neutralise the charges on dispersed non-settable solids such as clay and organic substances.

Once the charge is neutralised, the small-suspended particles stick together.

The slightly larger particles formed through this process are called microflocs and are invisible to the naked eye.

To achieve good coagulation and formation of the microflocs, a high-energy, rapid-mix to properly disperse the coagulant and promote particle collisions is needed.

Over-mixing does not affect coagulation, but insufficient mixing will leave this step incomplete. Proper contact time in the rapid-mix chamber is typically 1 to 3 minutes.

Diagram 3: Coagulation

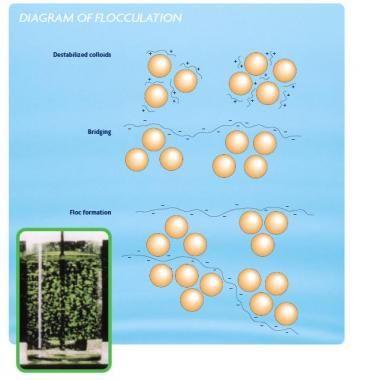

Source: sswm.info/content/coagulation-flocculationFlocculation is a process in which the colloids from a suspension form flocs of flakes.

During flocculation, the micro-particles and charged ions are attracted and attached to flocs. The impurities are adsorbed onto the coagulated flocs.

Flocs can further be removed by sedimentation, but only partially and for complete removal filtration may be necessary.

Gentle mixing stage, increases the size of submicroscopic microflocs to larger suspended particles.

With slow mixing, the microflocs are come into contact with each other. Collisions of the microfloc particles cause them to bond to produce larger, visible flocs. The floc size continues to grow through collisions and macroflocs are formed.

Separation is done (sedimentation, floatation or filtration) when the floc has reached its optimum size and strength.

Contact time for flocculation ranges from 15 or 20 minutes to an hour or more.

Diagram 3: Flocculation

Source: sswm.info/content/coagulation-flocculation

Documents on TWN about COD:- The determination of chemical oxygen demand in waters and effluents

- The Chemistry of Chemical Oxygen Demand

- COD Removal of Different Industrial Wastewater by Fenton Oxidation Process

- An Operator’ s Guide to Water Treatment Coagulants

- Coagulation and Flocculation

- Coagulation, flocculation and clarification

- Coagulation, Flocculation and Clarification of Drinking Water

-

Hi

There are lots of methods that can be used depending on the source of the high levels of COD and the type of the material. One can consider using an anaerobic digester or using physical methods such as screening, scheming and sedimentation. Physio-chemical methods such as coagulation and flocculation can also be used.

Hope this will help

-

Is it dissolved or suspended COD that is causing problems?

-

Hi Gary, A DAF removes FOG (fat, oil, grease) and particulate COD including colloids after coagulation-flocculation. Hence if turbidity at the DAF outlet = MBR inlet has increased along with the COD, then the DAF needs to optimized as recommended by Ciaran and Stephanus. However if the turbidity did not increase with the COD, then the additional COD is soluble and apparently readily biodegradable. In that case (electro-)chemical pretreatment would probably not be very efficient. An efficient and low cost alternative would be to add biosorption upstream of the DAF (in existing coagulation tank) using some waste activated sludge (WAS) from the MBR after regeneration. The WAS with adsorbed COD will be removed in the DAF. We remove up to 80% COD in 15 minutes via biosorption on regenerated activated sludge.

-

strength of COD for your waste stream - some details needed

Hello Gary - How are you?

What strength of COD are you talking about for your waste stream?

One plant I am working with right now has a COD strength of their influent from 6000mg/l to nearly 30,000mg/l depending on the time of year and their upstream process. The system is designed with an HRAD (High Rate Anaerobic Digester) ahead of the membrane bioreactor. This process dramatically reduces the COD and at the same time produces methane which is recovered and used by a CHP system for offsetting power consumption by selling it back to the power provider.

What is your bioreactor designed for COD wise?

-

To reduce COD

Add powder chlorine dioxide ClO2 to wastewater. It reduces both BOD and COD in extremely polluted water.

-

Please check TSS & turbidity before and after DAF, this will estimate performance efficiency of Daf and try optimise the coagulant and flocculent dose then. You might use some sieve tubes as well. If there is a sudden change in characteristic of effluent water please analyse that also. This may help to eradicate the COD problem

-

Hello Gary Our dual stage EC-AO electro chemical reactor process will provide multiple pretreatment constituent reductions including COD. Www.boydel.ca . The WaterMiner effluent delivered to your bioreactor will be clean clear and very stable meaning your bioreactor will be stable removing the smal dissolved fraction for digestion.

-

Gary Have you characterized the wastewater? Do you know what fraction of the COD is particulate, soluble, biodegradable and unbiodegradable? If some of the COD is particulate biodegradable then you could consider primary sedimentation. Patrick's proposal of fine sieves is also not a bad idea. Bu ultimately you would have to know in what form the COD is and how much. Do your perhaps have a process flow diagram of the current installation ? Regards

-

Hi Gary, If the influent has changed it is likely that the polymers used for the DAF also need to change so get some jar tests done and see if this can be optimised. This might be enough for your requirements. If not you will have to look at other options. Need more details on the plant to offer advice on this.

-

Have those compounds causing high COD been identified? Are those compounds biodegradable? Please ref to this link. It may help. Best regards http://www.d.umn.edu/~rdavis/courses/che4601/articles/Review%20of%20Wastewater%20Treatement.pdf

-

Start by optimisation of the DAF. 1. Coagulant selection + concentration 2. pH control (probe maintenance, ...)) 3. Ensure mechanical system is working( aeration, nozzles)

-

Hi Gary, as it is process water, May be you could reduce COD by reducing particular matter in the inlet (using a fine sieve). This can reduce COD about 10% in municipal wastewater, and is easier to install than a primary clarifier. But again, this depends if you have a relevant amount of suspended matter in your wastewater. Best regards.