Which is the best Wastewater Treatment technology?

Published on by Gamal Farahat in Technology

Which new technology is the most economic and efficient for water treatment plants according to you?

I am looking for some cost efficient and portable size, easy to operate, long shelf life technology or system.

Please give your suggestions and share your experiences with the existing technologies in your treatment plants.

Taxonomy

- Waste Water Technology

- Sewage Treatment

- Industrial Wastewater Treatment

- Wastewater Treatment

- Wastewater Treatment Plant Design

- Nanotechnology

- Water & Wastewater Treatment

- Waste Management

- Metering Technologies

- Technologies & Equiptment

22 Answers

-

Firstly you must know characteristics of your raw effluent. Treatment technologies depends on what parameters are present in your raw effluent and at what concentration. There is a lot of water treatment technologies. I will be lying to single out one if you did not disclose your raw effluent characteristics.

-

That is really a loaded question. You have everything from designs for anaerobic and aerobic secondary waste treatment, then you have to think about what you have coming in in order to choose the best technology for either anaerobic or aerobic or both. For someone to say that there’s a best technology one-size-fits-all, is either selling that technology, or they simply don’t understand the ramifications of choosing the wrong technology. I will say is that what you do upstream in your primary treatment is going to dictate heavily on what you can do downstream both economically and efficiently to meet your permit. In other words, do not skimp on the primary treatment because that will dictate the longevity and the likelihood of success In your secondary waste treatment. Then you want to consider if you need tertiary treatment. I mean what is the water going to be used for after treatment simply discharged or is it going to be reused and I want passion is it going to be reused. Does your permit allow for TKN versus ammonia? How much of your COD is BOD and does it fluctuate? Do I have any hydraulic problems or organic loading problems? This again goes back to primary treatment which would include your equalization basins. Since the name of the game and waste water is steady, when you have a lot of EQ upfront it helps so much downstream. Thoughts on this are in list so I hope you can take a look at your influential and assess it for proper design of all the systems. This is not an easy task and is industry dependent for sure. There are several modeling programs out there, that I would suggest that you invest in if you really are going to resign entire waste treatment system. And as always money, efficiency, maintenance, longevity and cost factor in. Some of these more sophisticated modeling programs tell you all the economics as well, including yearly spend, ROI, life cycle economy, etc. You have a lot of variables and this is no easy task so good luck to you. Please let me know if you have any questions and I’ll try and steer you in the right direction. Best, Sean. 239-989-3581

-

That is really a loaded question. You have everything from designs for anaerobic and aerobic secondary waste treatment, then you have to think about what you have coming in in order to choose the best technology for either anaerobic or aerobic or both. For someone to say that there’s a best technology one-size-fits-all, is either selling that technology, or they simply don’t understand the ramifications of choosing the wrong technology. I will say is that what you do upstream in your primary treatment is going to dictate heavily on what you can do downstream both economically and efficiently to meet your permit. In other words, do not skimp on the primary treatment because that will dictate the longevity and the likelihood of success In your secondary waste treatment. Then you want to consider if you need tertiary treatment. I mean what is the water going to be used for after treatment simply discharged or is it going to be reused and I want passion is it going to be reused. Does your permit allow for TKN versus ammonia? How much of your COD is BOD and does it fluctuate? Do I have any hydraulic problems or organic loading problems? This again goes back to primary treatment which would include your equalization basins. Since the name of the game and waste water is steady, when you have a lot of EQ upfront it helps so much downstream. Thoughts on this are in list so I hope you can take a look at your influential and assess it for proper design of all the systems. This is not an easy task and is industry dependent for sure. There are several modeling programs out there, that I would suggest that you invest in if you really are going to resign entire waste treatment system. And as always money, efficiency, maintenance, longevity and cost factor in. Some of these more sophisticated modeling programs tell you all the economics as well, including yearly spend, ROI, life cycle economy, etc. You have a lot of variables and this is no easy task so good luck to you. Please let me know if you have any questions and I’ll try and steer you in the right direction. Best, Sean. 239-989-3581

-

Membrane bio-reactor is by far the most efficient and cost-effective technology to scale. I believe this to be the industry standard for wastewater treatment over the next decade. My company has already seen this to be the case with projects in Asia and Australia.

If you would like to know more, please email me at andrew@waterandoilsolutions.com.au

-

Biological treatment purification of wastewaters Today concerning the treatment of waste water it is only a simple management of feces. UI allows you to swing pass feces instead of defecation until the place of their dispersion into the environment.

The use of treatment has no vocation to purify: it rejects everything in the enviroonement without any purification devices.

The - biological treatment - a comprehensive, definitive, economic, ecological and biological solution with immediate recycling of liquid out of the process for the watering of plant biodiversity: vegetable, pleasure garden, or an agricultural exploitation. A reduction in the levy of water on the groundwater: preservation of a scarce resource: water

-

Good day! For water purification in the production of palm oil, I would suggest :

- put a filter that would reduce oil loss and at the same time would have dehydrated him. This occurs without the heat treatment process takes place by simple laminar fluid flow. Further stock I would have handled in the hydro-wave machine, clearing a drain, Bessarabia water for reuse of its use.

If necessary, it will be possible to obsolete water without the use of reverse osmosis, new energy-efficient technologies. for the production of drinking water. The cost of desalination will not exceed 0.6 kW per 1m3. I misspoke and was not mistaken - 0,6 kW.

-

If You are looking for energy-efficient technology for wastewater treatment - I will be glad to help. We developed the technology in which energy consumption is reduced THREE (3) times, the footprint is five times the cost of commissioning was reduced by 30%. Calculate the cost of cleaning at home themselves, based on the cost of electric power of 0.7 kW per 1 m3 of wastewater. If there is a technology with lower costs - I am willing to apply. If you find this interesting or worthy of attention - please - send presentation equipment with photos. Looking for companies interested to become a representative in their own country this equipment.

E-mail TUMENTSEV@INBOXRU

-

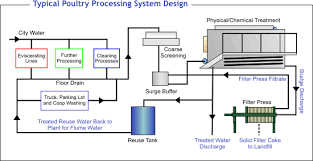

We have a great deal of experience in treating wastewater from food processing facilities. Here is our typical configuration. We also have many years of experience in treating water from industrial laundries. Our equipment can economically reduce the following waste water / process

water constituents (and others as well) to well below required levels in most cases:Phosphorus

Metals

BOD / COD

TSS

Oil & Grease

TKN

Contact us at www.pollardindustries.com

-

Good day!

Glad to see the representatives of Kuwait - mills, which I really liked. I am ready to offer technology and equipment for wastewater treatment with energy consumption FOUR times lower use of conventional technology, which significantly affects the cost of cleaning. Especially in Kuwait, biological treatment is not in a full measure ( on the beaches of El Kuwait there are signs with the prohibition to swim in this area) due to the high ambient temperature, which significantly affects the microorganisms. Although the city is in need of large quantity of industrial water - water after purification in wastewater treatment plants cannot be applied for such purposes.

We propose a technique in which :

- the waste water can be cleaned in a very short amount vremeni;

- VERY LOW energy consumption;

- ON a VERY SMALL AREA;

with the possibility of return waters for technical purposes, etc.

my e-mail tumentsev@inbox.ru

-

Every wastewater is different, hence, one technology which is economical and efficient for that wastewater treatment in that economical range, will not be economical/efficient for another type of wastewater.

Also, both the terms are contradictory, Economical and Efficient for New Technology.

Consider, desalination process, RO based desalination is economical compared with evaporation and condensation. But comparatively, has less efficiency. Still generally incorporated in various desalination project.

However, oil-rich countries do the later one, as there is no economical constrain.

As you are looking for some cost efficient and portable size, easy to operate, long shelf life technology or system.

but the question is for which type of wastewater. This is very general question.

Kindly enlighten us regarding the type of wastewater.

So that, actual experts, sorry marketers, can give their suggestions and share their experiences with the existing technologies in there respective treatment plants, for your kind of wastewater.

-

What technology wants to get the customer to wastewater treatment ???

1. Takes no more territory;

2. Not expensive to maintain, it is desirable - automated;

3. With the low cost of treatment;

4. With the possibility to re-implement the purified water.

we developed this technology and successfully apply for more than six years. With it we clean - wastewater meat processing plants for slaughtering animals, breweries, household wastewater, dairy (Danone) oil-extracting enterprises, sewage pig and so on.

Factors that we present - are unique in the world because the average figure for energy consumption per 1 m3 of treated wastewater and decontamination of 0.7 kW, the required space is reduced to five (5) times sraneniyu with biology, the cleaning process takes place behind closed doors - from equalization (receptacle) and to discharge clean water .

The equipment is fully automatic, to oversee them need one operator on duty.

Sanitary zone is reduced to 20m, which means the possibility to clean drains in the next room. !!!!!!!!!

Mechanical impurities and organics are processed and disinfected in the equipment turning into mechanical impurities, not larger than 20 nm, that for dehydration allows you to use them as organo-mineral fertilizers !!!, rather than stored as an activated sludge at a separate site.

This equipment can be operated periodically (at long intervals) at a steadily high quality cleaning.

If you're interested - write - to answer further questions. -

Soneco TM (Sono-Electrochemistry) or the combined process of Electrolysis & Power Ultrasound for chemical-free coagulation and flocculation, disinfection when required, with traditional downstream clarification i.e. lamella plate settler or dissolved air flotation tank.

As stated by others below, it is heavily dependent on the exact waste stream and the contaminant loading of that waste stream as this can vary massively and does make a difference to the required technology because some may be more efficient on that particular waste stream. For example, when compared with traditional treatment and chemical dosing- We save roughly 40% for phosphate removal on a particular site. If this site also required Iron removal and was required to dose Sodium Hydroxide for pH adjustment this could be increased.

Electro-coagulation is a "clean" technology, utilising the electron as the reagent therefore, no harsh chemicals are required to be transported, handled, stored with no potential for chemical spills or leaks. The process is energy efficient and can be powered by renewable energy sources such as solar PV, Fuel Cells- MFC/HFC's, Wind, Hydro and ideally suited to remote locations where regular operation would be impossible. The process is fully autonomous allowing feedback and control from locations all over the world.

Electro-coagulation alone can be quite tricky and to be frank, inefficient. With the addition of a high power factor power device and ultrasound this process can now be deemed efficient in energy and cost. Cavitation that takes place due to the ultrasound continuously "exfoliating" the electrode surface to maintain an even, reactive treatment surface and to massively extend the electrode life. There is no requirement for filters or membranes and no moving parts- the only maintenance requirements being the electrodes potentially every 3-6 months.

Our units range from small, communal based WTP (i.e. 2000 litres/day for 200 people) powered by one solar panel up to around 150 MLD industrial and municipal WTP.. With Sono-electrochemistry the possibilities of contaminant(s) loading it can treat is immense and to optimise the process, the only variable you will need to change (on site) is the amperage and this would be done automatically based on feed-water quality. So not only is it simple to maintain but also to operate and control.

There is no silver bullet and of course, clever integration is key at present. Although, I would say if *particular* SONO-electrochemistry processes are the closest you can get to that silver bullet with minimal infrastructure, additional equipment/ technologies required.

And when I say particular- I just want to note that this is infact a "World-first patented process" so very novel and as you all know- the proof is in the pudding and unfortunately, this is the only real negative in the EC/Chemical free market - specifically Sono-electrochemistry is the lack of data, hard evidence.

So, trials are being undertaken at present with one of the top UK utility company on a WWTW with a phosphate problem and consent for further trials. EC has been trialled and tested and as far as I am aware the main problems (coherently) found at each site was the inefficieny of the electrodes, high energy consumption and the addition of sodium chloride in an attempt to clean the electrodes- raising the OPEX and creating problems down stream. I can see that we have overcome these issues and can now move forward with solid data of this and how it was achieved.

I have attached a very brief PDF on Soneco below. If anyone would like further information, please let me know and I can send over some tech sheets/we can discuss.

Besides promoting this process, I do hope that this area of advanced water treatment is of interest to the market as a route that companies will start taking more seriously now that the process is optimised and proven.

I would be interested to learn others thoughts on using this technology.

1 Comment

-

Is Electrocoagulation is better than SBR or MBBR??

Please share technical as well as commercial justifications.

-

-

The answer depends very much on the source water quality and quantity for the water treatment plant. There is no single cost-effective technology which is suitable for all sizes of water treatment plants and sources of water.

-

Dear Gamal Farahat ,

What is the source and amount of wastewater? What are you manufacturing?

1 Comment

-

I'm Talking About The Sewage Water Treatment Generic

-

-

FCR (or for portability FCR Bluehouse) http://organicawater.com/organica/solutions/organica-fcr , https://youtu.be/gwrkr4TQlYc. It also very much depends on the type of wastewater you need to treat

2 Comments

-

Please share technical details at servicesenvirochem@gmail.com

-

did you visit PGESCo company @Egypt Before?

-

-

check out www.biocycle.ie

-

Each supplier provides the "best" and "new" technology. MBR is a good example of such push technology which is the "best" for the suppliers of membranes but not really for their owners and users considering its high investment and operating costs.

Unfortunately there exists no single silver bullet "best" technology for all kinds of wastewater and for all treatment steps that will meet all criteria and constraints for any application.

Example: Over 90% of the organics (COD, BOD) in many wastewaters can be converted to green energy (methane) as opposed to consuming even more energy in conventional treatment such as CAS, SBR, MBR, MBBR, ... considered as "best" by their suppliers.

1 Comment

-

absolutely

-

-

Hi, I will agree with Mr Little. It is really a case by case study. In my opinion MBBR are really easy to operate, suitable for remote places and small WWTP. Particularly when high infiltration due to storm warter are present - the biomass never leave the tank. When high effluent quality is needed an MBR may be more cost effective and easy to operate than any other technology. SBR and Conventional plants have also their advantages.

When retrofitting an existing plant MBBR and MBR could be a cheap solution.

-

It depends on your circumstances - each process has benefits. The important thing is to examine what your current circumstances are and undertake some planning for the future. What can your community afford?

-

Hi, SBR and MBR are considered cost efficient , portable size and easy to operate wastewater treatment system.

1 Comment

-

For Sewage Treatment Plant.

1 Comment reply

-

What You need for this treatment plant wastewater ?

-

-

-

We approach WWTPs the same way we approach dairy and hog operations. The solids are an asset and should be harvested not consumed by bacteria.

3 Comments

-

Sergey, I don't understand the first part of your question. I can say, however, that the system we designed for a medium sized US city would save them $1,000,000 per year and still leave the project owners a like amount.

-

Very interesting - on what basis are You doing this and what are the costs for electric energy and what is the cost of cleaning ?

-

The separated solids can be fuel in a biomass gasification system. The separated water can continue to be treated or can become distilled water.

1 Comment reply

-

By what process do You achieve that ?

-

-

-

That's an easy one- the ones I sell!

1 Comment

-

Jeff Pollard Please share some facts/case study info instead of just using the site to promote your products. Thank you!

1 Comment reply

-

There is no specific question, so there is no specific answer. Thanks and have a great day...

-

-